Agni Link is not just for releasing BoMs into Manufacturing

What else Agni link can do?

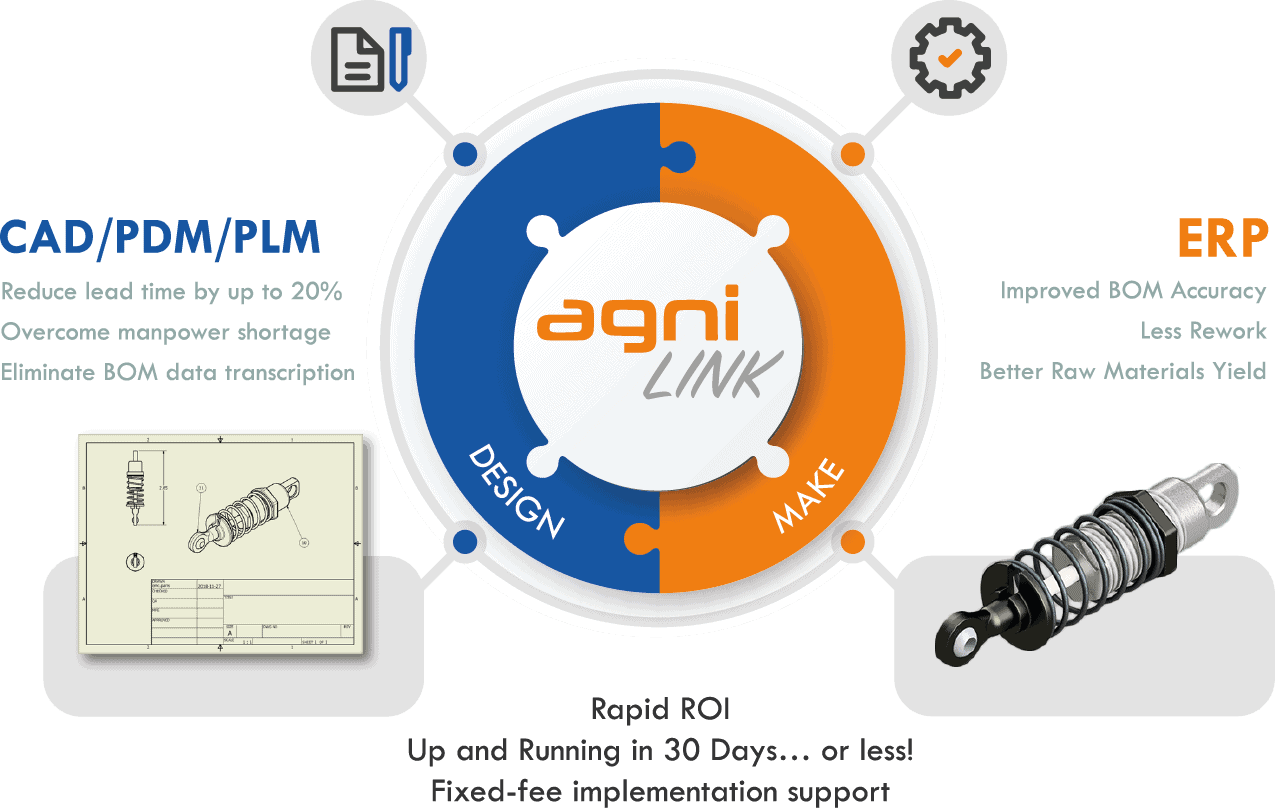

1. Support seamless integration

While the release of the BOM is an important part, Agni Link provides a comprehensive suite of capabilities that support seamless integration and communication between design and manufacturing teams.

2. Real-time synchronization

It allows real-time data synchronization between CAD and PLM systems, ensuring that all stakeholders are working with the most up-to-date information, and it offers collaborative design revisions.

3. Increasing accuracy, productivity and communication

Agni Link emerges as a crucial tool for businesses seeking for optimizing their journey from design to production by increasing productivity, accuracy, and communication across the product lifecycle.

4. Overcome shortage of qualified workers

Agni Link is a game-changer in overcoming the challenges posed by the shortage of qualified workers in various industries. With its advanced automation and integration capabilities, Agni Link significantly reduces the need for extensive manual data entry and labor-intensive tasks in areas such as design, engineering, and manufacturing. By streamlining processes and ensuring data accuracy, it empowers existing personnel to work more efficiently and take on more responsibilities, effectively bridging the gap created by a lack of skilled workers

5. Rapid ROI

By automating data synchronization and integration processes, it reduces manual labor, minimizes errors, and accelerates project timelines. This efficiency translates into cost savings, as fewer resources are needed for tasks that Agni Link can handle seamlessly. Moreover, by ensuring data accuracy and real-time collaboration between different teams and software systems, Agni Link enhances decision-making and overall productivity.

Conclusion

Elmo Solutions Inc.

797, boul. Lebourgneuf, suite 300

Quebec (Quebec) G2J 0B5