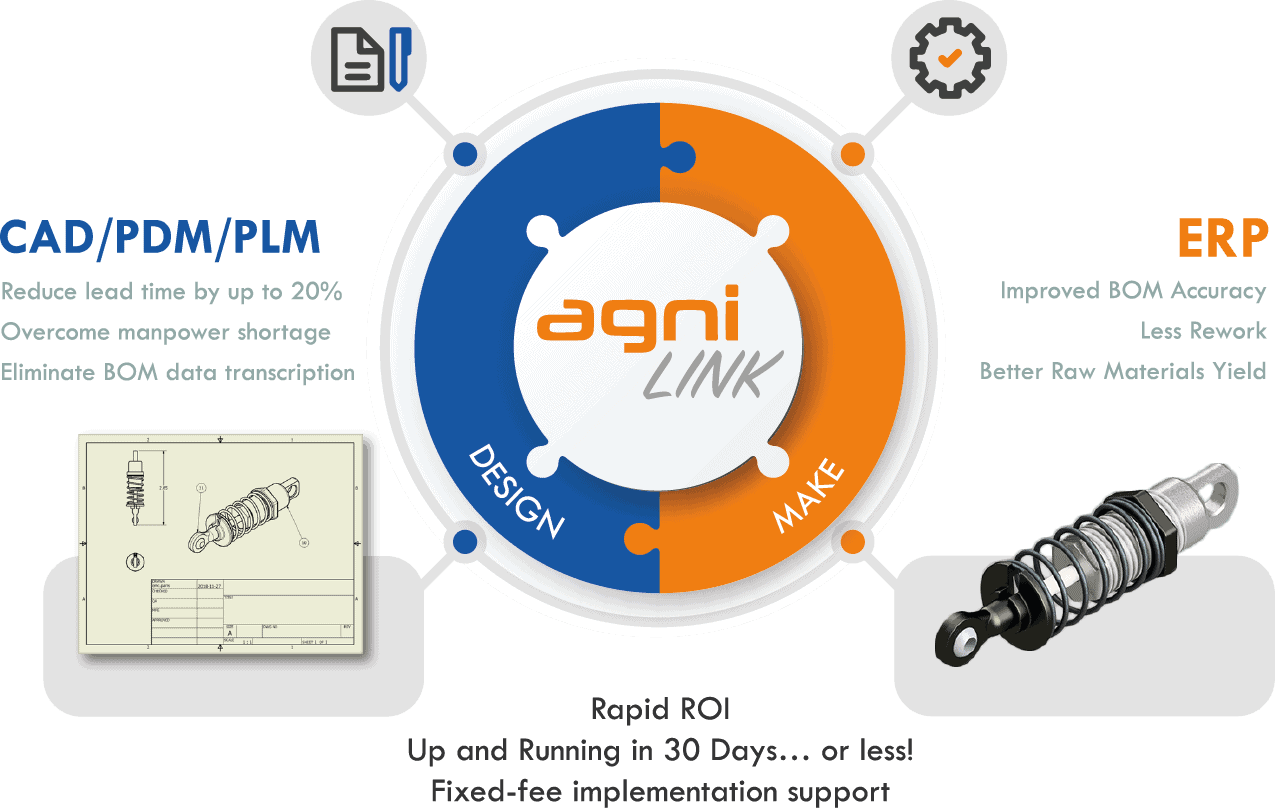

Agni Link : real-time data transfer between CAD/PDM/PLM and ERP

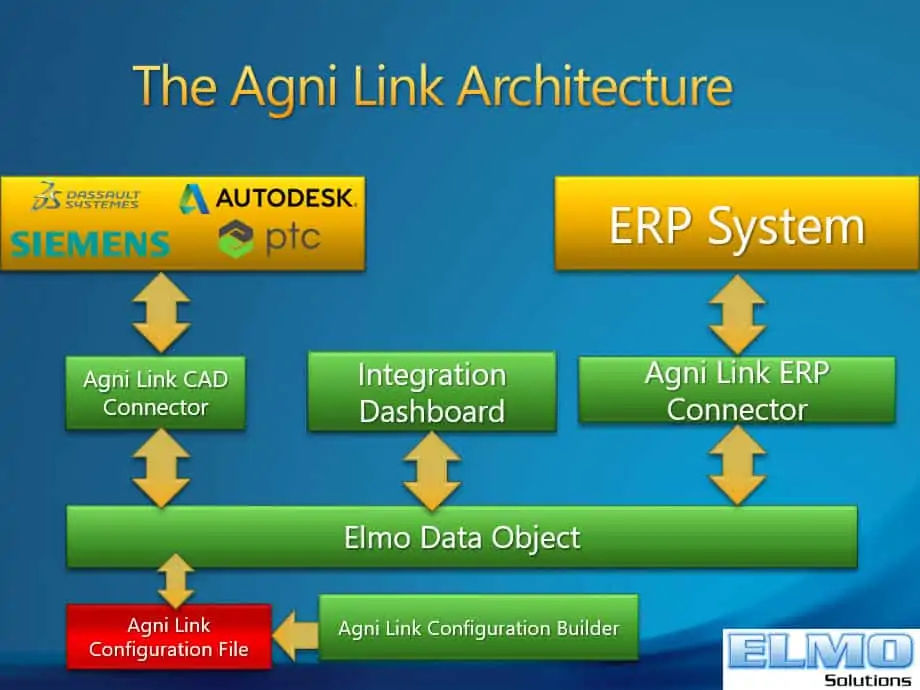

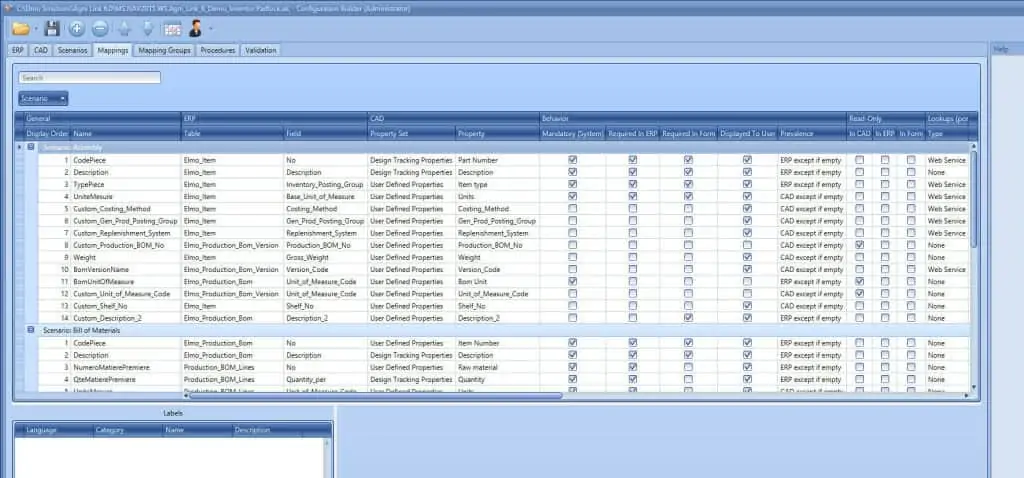

Agni Link automates the transfer of Bills of Materials using an add-in to CAD/PDM/PLM applications by Autodesk, SOLIDWORKS, PTC (Creo, Windchill) and Siemens (Solid Edge, Teamcenter), just to name a few. It brings your data from both information silos into one common data object. You can easily define simple rules, so the discrepancies found between your systems are resolved in real-time automatically. Easy, error-free, accurate and reliable. The Elmo way. And if you are not quite happy with the mappings and their behavior, you can easily edit them all by yourself — without any programming!

THAT is the leading edge in the world of CAD to ERP data integration.

Agni Link, the brainchild of Elmo Solutions’s R+D team, is the result of over 30 years of experience in the CAD, PDM and PLM domains. Our wizards have designed the link application with quality obsession. Our experts chose the most important feature that is often left out in the industry: the customer’s freedom of choice.

THE AGNI LINK CAD ERP INTEGRATION PROCESS

Agni Link can process real-time, bidirectional data integration. Also, you can synchronize a wide range of data from either side, including, but not limited to:

- Product Data: automatically updates and/or creates component, subassembly or assembly data in ERP system.

- Bills Of Materials: automatically updates BoM items quantities in ERP/MRP system.

- Parts and Items: in some ERP systems, it can work with more than one part/item table at a time (e.g., Master Catalog, Engineering Part, etc.).

- Routing Instructions: edits and automatically inserts routing data into a CAD document.

- Raw materials: using raw materials available in the ERP system, end-users can optionally supply raw material information, including quantity and units of measure. Agni Link can even automatically extract geometric information (mass, length, area, etc.) of certain parts and use it as the raw material quantity.

- Revisions: Agni Link faithfully transfer version and revision history data between your engineering and manufacturing environments.

- Vendor, Pricing, etc.: Users can see the procurement data from the ERP system (vendor information, costing, even available quantities). All in real-time!

- Engineering Change Management:Engineering Change Requests, Orders and Notifications (ECRs, ECOs and ECNs) can be mapped bidirectionally between engineering and ERP applications, allowing joint Change Management.

- Jobs: Job-centric ETO manufacturers can map engineering documents into jobs or work orders, rather than Bills of Materials.

- Quotes: Users can instantly switch from a product design integration to a quote integration… or any other type of integration, for that matter. The only limitation is your imagination!

-

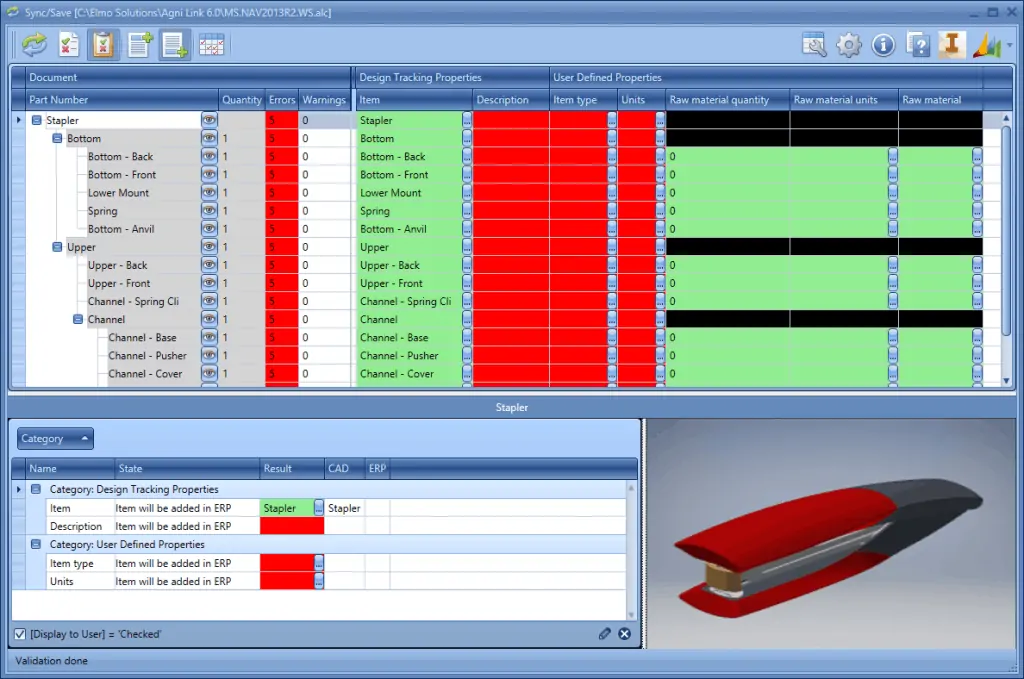

- Agni Link data object fetches all the mapped CAD / PDM / PLM and ERP data.

- You define rules, and the bridge automatically resolves discrepancies found. Agni Link indicates decisions made automatically by through color-coding of data in the Agni Link Integration Dashboard. Of course, you can, at any time, either revert to the previous value, or select a different value of your own taste, as long as it is acceptable to the ERP system. If it is not, don’t worry, Agni Link will let you know right away!

- The Agni Link Integration Dashboard presents the “merged” CAD and ERP integration data to the end-user. You can use it to display engineering data, but also ERP data such as any vendor, costing and availability. Users can use these informations to make better design decisions. They also use a color-coded dashboard that indicate any potential issues with the BoM data to be transferred.

- Users can use edit functions to quickly validate and populate Bill of Materials data. Lookups performed in real time on the ERP system, ensuring that anything sent to the ERP has properly checked the ERP system’s own business logic. The results translate into much greater BoM accuracy. When Agni Link properly verified all data, it sent it back to CAD and ERP for the final synchronization.

- End-User updates data simultaneously in both environments, upon final confirmation. He/she can even create automatic data (Items, Bills Materials, Routings, etc.) that does not exist yet in the ERP system.

AGNI LINK ACHIEVES OPTIMAL INTEGRATION BY PROCESSING THE DATA THROUGH A SIMPLE AND EFFICIENT PROCESS

Not just about BoMs…

Many different integrations are possible!

Customers strongly require for Agni Link to involve Bill of Materials (BoM) data.

Agni Link can put it’s architecture to work to integrate other ERP data:

✔ Business Process Management (BPM) data

✔ Bills of Materials (BoMs)

✔ Components

✔ Document management

✔ Estimating

✔ Jobs

✔ Product catalogs

✔ Parts catalogs

✔ Product data

✔ Production orders

✔ Production schedules

✔ Supply chain data

✔ Technical documentation

✔ Work orders

✔ Routing data

Agni Link’s unique “three-bucket” architecture makes for the most flexible and reliable data exchange process while allowing customers to map all the available data models entirely.

When you update a component or assembly, you may enter and/or edit CAD data:

- You can do it the first time, or at any moment afterwards. Also, in the case of PDM and PLM systems, you can use selectable events like : new revision, new version, approval, release, etc.

- The Integration Dashboard let you use “live” values taken from the MRP, ERP, BPM, CRM or other application :

PLM PDM CAD data can be easily exchanged bidiretionally, in real-time, thanks to the Agni Link advanced architecture. Connectors for popular engineering applications from Dassault systèmes (SOLIDWORKD, SOLIDWORKS PDM, Catia, Enovia), Autodesk (AutoCAD, Autodesk Inventor, Autodesk Vault), Siemens (Solid edge, Teamcenter) and PTC (Windchill, Creo) can provide an easy, yet powerful integration with any ERP system.

The Agni Link Integration Dashboard monitors the current state of the integration. Users have perfect control over the whole process, while automating the menial tasks.

Also, the Dashboard simultaneously displays information for the entire Bill of Materials and specific component data. It makes extensive use of color-coding to indicate any issues or warnings prior to the actual integration.

GET A QUICK RETURN ON YOUR INVESTMENT WITH AGNI LINK

- Virtually eliminating manual and/or erratic transfer of data

- Dramatic reduction of errors on the factory floor, as a result of increased BoM accuracy

- Low TCO (Total Cost of Ownership) of the solution, due to self-reliance of customers (custom solution without programming)

TAKE A LOOK AT THE AGNI LINK QUICK DEMO VIDEOS

The Agni Link Configuration Builder brings huge benefits. Its unique features give customers full control over their CAD and ERP integration… without any programming!

This is not just about CAD… PDM and PLM are in the picture too!

- Users can work with a richer data set that also includes BoM data that is not normally found in CAD data

- Select the events or workflows (check-in, approval, new revision, etc.) that will automatically trigger the integration process

When the user set up specific milestones in your business process, your PDM system will automatically initiate synchronization. It’ll release the Engineering Bill of Materials data to the ERP system, thus updating product data in a timely fashion.

You’re already in the PLM era? Agni Link can be your reliable companion. Our versatile application architecture will allow you to link procedures, user manuals, schematic, marketing, service, quality, support and many more, by merely changing the Agni Link configuration.

Thus, Agni Link will allow bidirectional communication for all documents and files throughout the entire production/supply chain. That way, there won’t be an annoying « black box » effect for any stakeholders. Indeed, approval process will be distributed to prevent all discrepancies in real time. Also it’ll identify who made changes (and why).

Your PLM efficiency is based on the coordination of product data. It includes : changes, status, configuration, document management and resources planing. For this kind of data, you imperatively need the best integration for your PDM/PLM and ERP data.

Stop leaving money on the table, and INTEGRATE: the sooner, the better!

You can interconnect all your software with a powerful, versatile and reliable bridge. To find out If you wonder how it could work with your particular system, don’t hesitate to contact us.

Will Agni Link support my CAD and ERP systems?

Elmo Solutions’ Agni Link is currently available as an add-in to the following platforms:

CAD/PDM/PLM applications

- PTC Windchill

- PTC Windchill

- Dassault Systemes SOLIDWORKS

- Dassault Systemes SOLIDWORKS PDM Professional

- Dassault Systemes PDM Enterprise (PDMWorks Enterprise)

- Dassault Systemes PDM Workgroup (PDMWorks Workgroup)

- SOLIDWORKS Manage

- Microsoft Excel

- Autodesk Inventor

- Autodesk Revit

- Autodesk Vault

- Autodesk Vault Professional

- AutoCAD

- AutoCAD Electrical

- AutoCAD P&ID

- Autodesk Map

- AutoCAD Architecture

- AutoCAD/Mechanical

- Autodesk Civil 3D

- Dassault Systèmes CATIA

- PTC Creo

- Siemens TeamCenter

- Siemens NX

- Siemens Solid Edge

- EPLAN

- Pulsonix

- More to come

Planned CAD/PDM/PLM applications

ERP Integrations

- Acumatica

- Microsoft Dynamics 365

- IFS

- Priority Software

- JD EDWARDS

- SAP ERP

- SAP S/4HANA

- SAP Business ByDesign

- SAP Business One

- SAP Business All-In-One

- Oracle NetSuite

- Microsoft Dynamics NAV (Navision)

- Microsoft Dynamics GP (Great Plains)

- Microsoft Dynamics AX (Axapta)

- Microsoft Dynamics SL (Solomon)

- MIE Trak Pro

- ODOO

- Orchestra pour PME

- Acomba Accounting Suite

- More to come

Planned ERP Integrations

- Aptean (Consona) AXIS ERP

- Aptean (Consona) DTR ERP

- Aptean (Consona) ENCOMPIX ERP

- Aptean (Consona) MADE2MANAGE ERP

- Aptean (Consona) ROSS ERP

- Epicor ERP

- Infor SyteLine

- Infor Visual

- Macola ERP

- Oracle ERP Cloud

- Plex ERP

- QAD

- Sage 100

- Sage 200

- Sage X3

- More to come